Service hotline

+86 0755-83975897

en

en Release date:2021-12-28Author source:KinghelmViews:2399

In automation applications, frequent work may cause connector wear and damage connectivity and reliability. Contactless connectors provide a new alternative.

Mechanical connections face challenges in industrial applications that work frequently. When two mating interfaces interact, inevitable wear will lead to a series of contact related failures and maintenance problems. With the increasing demand for interconnection in automation and industry 4.0, suppliers are designing new contactless connector technology.

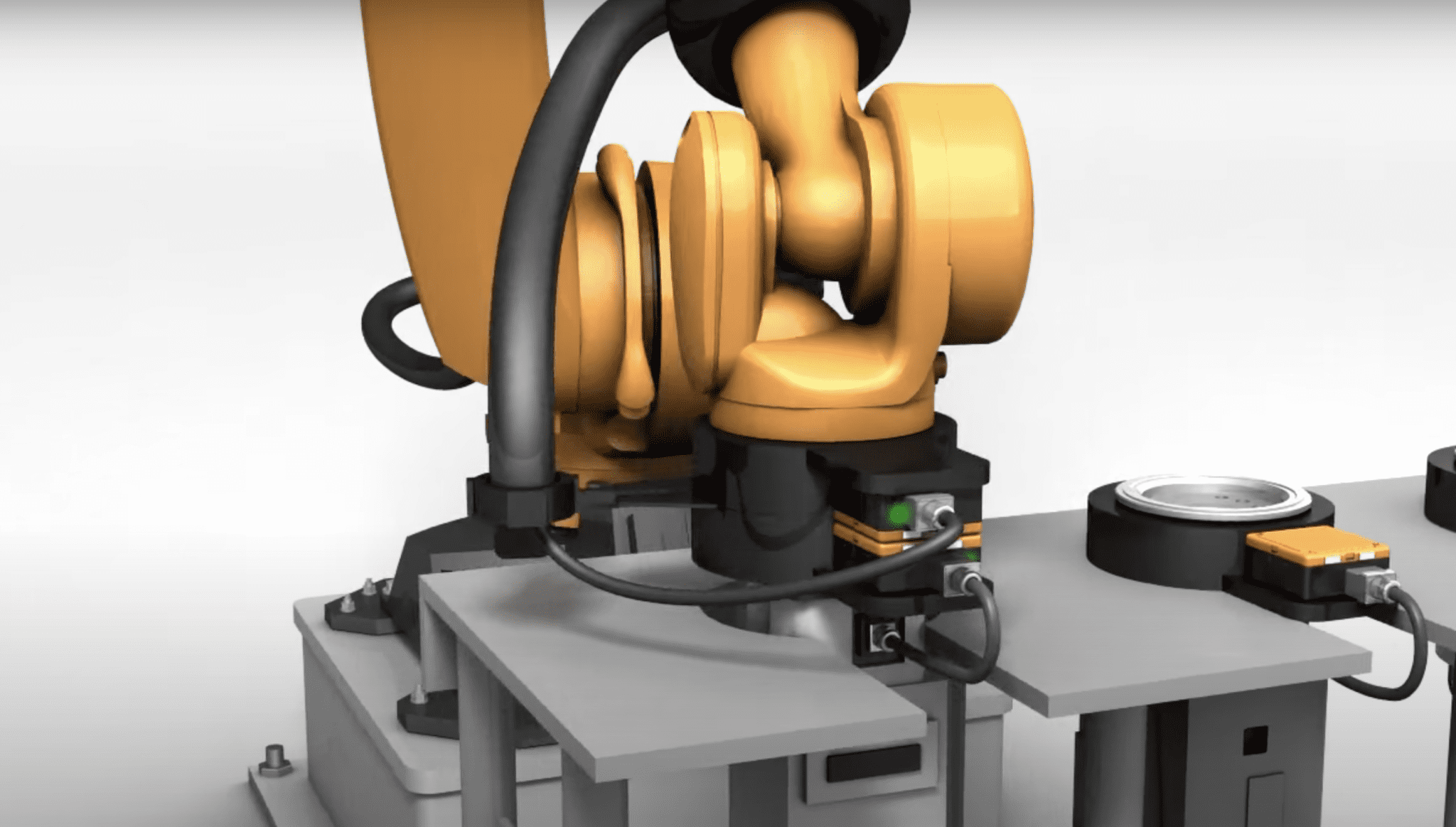

Contactless connector is an emerging solution in the high reliability market. Traditionally, connectors in the market need a large number of cooperative applications, including manufacturing and other automation industries. A new solution, such as weidmueller contactless connector, is the first connector designed for high reliability applications. It can be used in the automation process to replace the connection that must be manually inserted before.

Work closely with leading German carmakers, weidm & uuml; Eller's freecon connectors are used in automotive manufacturing and other fields.

This contactless solution uses inductive resonance coupling to reliably transmit power up to 240W. Contactless connections provide a variety of performance and advantages. They help to improve the level of automation and optimize the production process, making new design and application possible. For example, automate the charging of driverless transportation systems.

Rene & middot, product engineer of weidmueller; "Contactless connectors are suitable for a wide range of fields, such as machine construction, robotics, material processing, and even renewable energy. They can be easily transformed, so they are also an attractive solution for existing factories," hesman said

Contactless connector applications include:

1. Tool changing device, such as equipment for automobile production.

2. Load equipment for smaller driverless transportation systems, mobile manufacturing systems or trams.

3. Clean room manufacturing of medical consumables.

Weidmueller's freecon connector provides extremely low transmission loss and efficiency of up to 93%.

Due to the high flexibility of non-contact connection solution. The connection can be accessed from any direction. Once the two modules are opposite each other, a connection is established. The connection remains stable even when rotational motion occurs.

Hesman said: "With the increasing automation of industry 4.0 technology, contactless transmission will continue to play an important role. Why? Because unlike traditional plug-in energy transmission, contactless transmission will not cause any mechanical wear. This extends service life, reduces downtime and time-consuming maintenance work. In addition, contactless transmission provides a basis for automation and process optimization New opportunities. "

Through PLC control, the auxiliary side can be opened or closed using the main side. In addition, the plug and play function means that there is no problem in transforming non-contact products into existing systems.

Power is transmitted through inductive resonance coupling. The utility model has the advantages of no wear, reliability and high efficiency. The added value is the significant power density, which is twice that of comparable solutions on the market. At the same time, the maintenance cost is lower.

Contactless Industrial Solutions

In the industrial field, non-contact technology provides many opportunities for high-performance automation. Its advantages are as follows:

·Wear free electrical connections can be switched in a controlled process.

·Flexibility is high due to unlimited access options.

·Completely prevent the pollution of humidity and dirt.

·Flexible installation options.

·Push pull power connection is adopted for rapid commissioning.

Case study of contactless connection

German freeze dryer intelligent factory has developed an automatic loading and unloading system. The freeze dryer is loaded by a robot that can move horizontally along the toothed belt. The stepping motor of the robot driver is powered by a rechargeable battery. The non-contact connection is used to charge the battery.

At the parking position in front of the freeze dryer, the loading device obtains a new non-contact power supply, and the communication with the controller is wireless communication. The compact design makes the loading and unloading system an ideal solution for the production of freeze dryer under clean room conditions. Without Contactless charging, it is inconceivable that this application can be realized.

Another non-contact connector application is tram manufacturing. Small space requirements, high flexibility and modularity are important to create solutions for clean rooms and hygiene demanding environments. The autonomous power supply, combined with Wi Fi data connection, provides the maximum mobility for the tram system. The power supply is inductively transmitted through the magnet proximity system, and the charging can be positioned automatically.

Non contact cleaning room

The main advantage of this solution is that it can always meet the requirements of protection level IP65. In the traditional plug-in connector, it needs to be inserted and pulled out frequently. This is a potential source of pollution in clean rooms, which can be avoided by non-contact charging.

For example, plug-in connections inevitably lead to particle contamination in clean room applications. Contactless power transmission provides another option. Free contact creates clean connections and, if necessary, transmission through glass walls. This can protect products and processes from pollution in typical applications, such as medical technology, electronic manufacturing or food industry.

When the manual plug-in connector reaches its limit, contactless transmission technology opens up a new perspective for automation.

This content comes from the network / Shenzhen connector industry association. This website only provides reprint. The views, positions and technologies of this article have nothing to do with this website. If there is infringement, please contact us to delete it!

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853