Service hotline

+86 0755-83975897

en

en Release date:2021-12-28Author source:KinghelmViews:2607

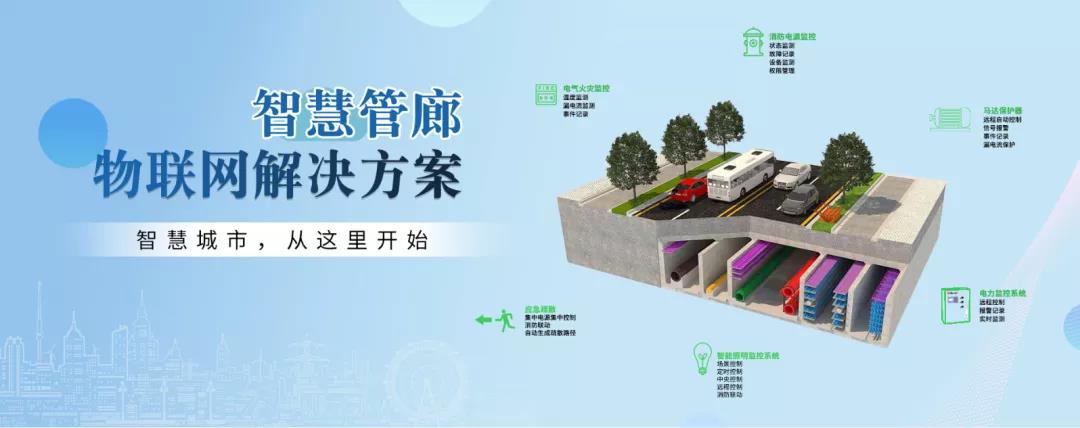

01 Summary

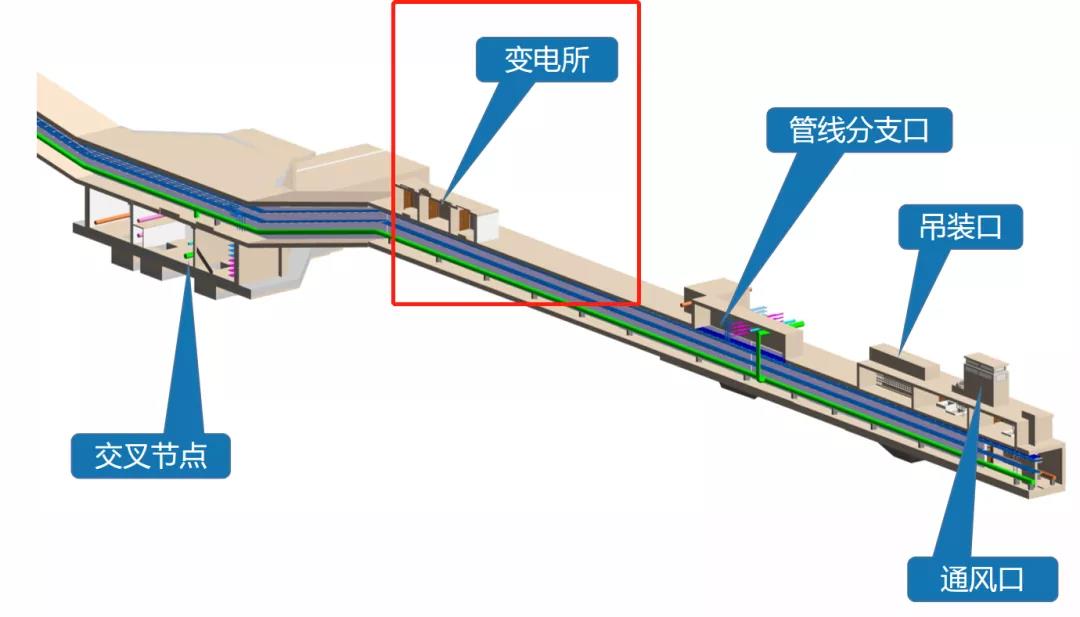

The comprehensive pipe gallery is generally a structure and ancillary facilities built underground to accommodate two or more types of urban engineering pipelines. The municipal public pipelines such as power, tap water, heat, gas, telecommunications and network are centrally laid in the same structure according to the planning requirements to implement the municipal public tunnel space of unified design, construction and management, and also has drainage, ventilation Lighting, communication and monitoring functions. The main function is to avoid repeated excavation of urban roads, reduce urban pollution, provide various energy and communication for urban operation, and ensure urban operation. Whether the bearing pipeline fails or its own auxiliary equipment fails, some functions may be paralyzed. Therefore, various on-site sensors need to be set up to monitor and control the operation of internal facilities in the pipe gallery when building the comprehensive pipe gallery. It usually includes: auxiliary ground and internal power supply system of pipe gallery, lighting system, fire control system, drainage and smoke exhaust system, ambient temperature and humidity, combustible gas detection, access control, intrusion detection, video, patrol, etc.

02 Project requirements

Because of its use, the pipe gallery has become the main artery and lifeline of urban power and communication, and its importance is self-evident. There are mainly the following requirements for the monitoring and control of the Comprehensive Pipe Gallery:

2.1 Monitor the electrical parameters of transformers and switchgear in aboveground substation;

2.2 Monitor the electrical parameters of distribution boxes and cabinets inside the pipe gallery;

2.3 Remote control and infrared induction control of lighting in the pipe gallery;

2.4 Monitor the leakage current and cable temperature of the distribution circuit inside the pipe gallery and give an abnormal alarm;

2.5 Monitor and give abnormal alarm to the power circuit of fire fighting equipment in the pipe gallery;

2.6 Monitor and control the status of fire doors in the pipe gallery;

2.7 There are obvious indicating lamps at the fire evacuation passages and exits in the pipe gallery, and emergency control can be carried out through different emergency plans;

2.8 Start and stop the water pump according to the water level of the sump inside the pipe gallery, and start and stop the exhaust fan according to the internal combustible gas concentration and smoke;

2.9 Monitor the internal ambient temperature and humidity of the pipe gallery, and monitor, alarm and linkage control of combustible gases such as smoke and methane;

2.10 Monitor the access control of pipe gallery and illegal intrusion alarm;

2.11 Video monitoring and patrol system inside the pipe gallery;

2.12 The monitoring software adopts B / S architecture, accesses the above monitoring data, provides data monitoring and abnormal alarm through browser, mobile app or SMS, and can release maintenance, patrol inspection and emergency repair dispatch tasks through the system.

03 Solution

The standards followed in this scheme are:

GB50838-2015《Technical code for urban comprehensive pipe gallery Engineering》

GB/T 14285-2006《Technical specification for relay protection and safety automatic device》

GBT 14598.300-2008《General technical requirements for microcomputer transformer protection device》

GB/T 2887-2011《General specification for computer field》

GB50052-2009《Code for design of power supply and distribution system》

GB/T 20965-2013《HBES technical specification for control network residential and building control system》

GB 50116-2013《Code for design of automatic fire alarm system》

GB 14287-2014《Electrical fire monitoring system》

GB25506-2010 《General technical requirements for fire control room》

GB50116-2013《Code for design of automatic fire alarm system》

GB28184-2011《Fire fighting equipment power supply monitoring system》

GB29364-2012《Fire door monitor》

GB51309-2018 《Technical standard for fire emergency lighting and evacuation indication system》

JB/T10736-2007《Low voltage motor protector》

GB/T15576-2008 《Low voltage complete reactive power compensation device》

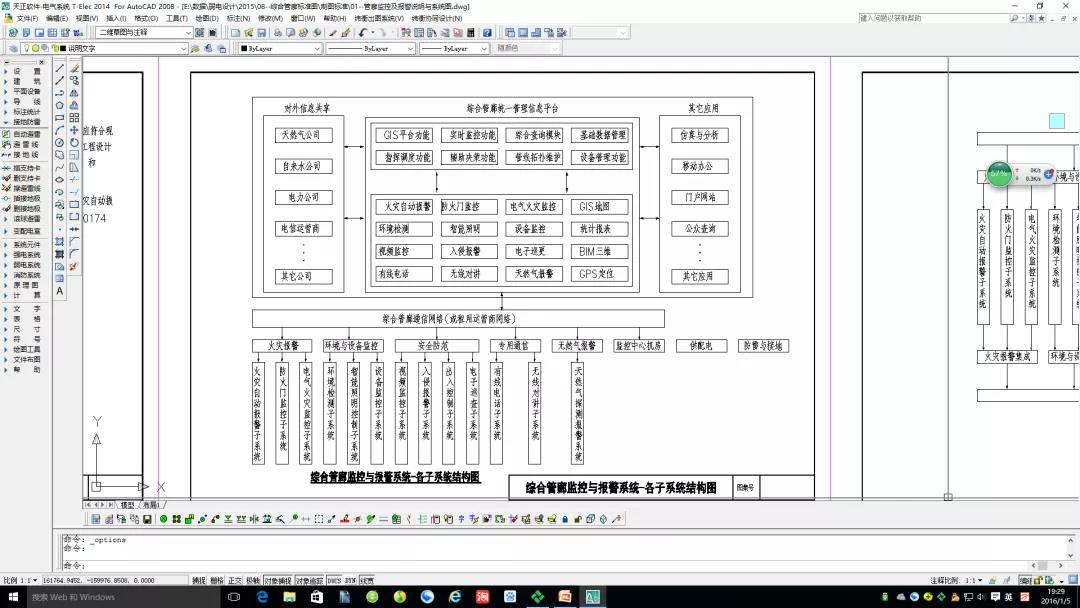

04 Conceptual design

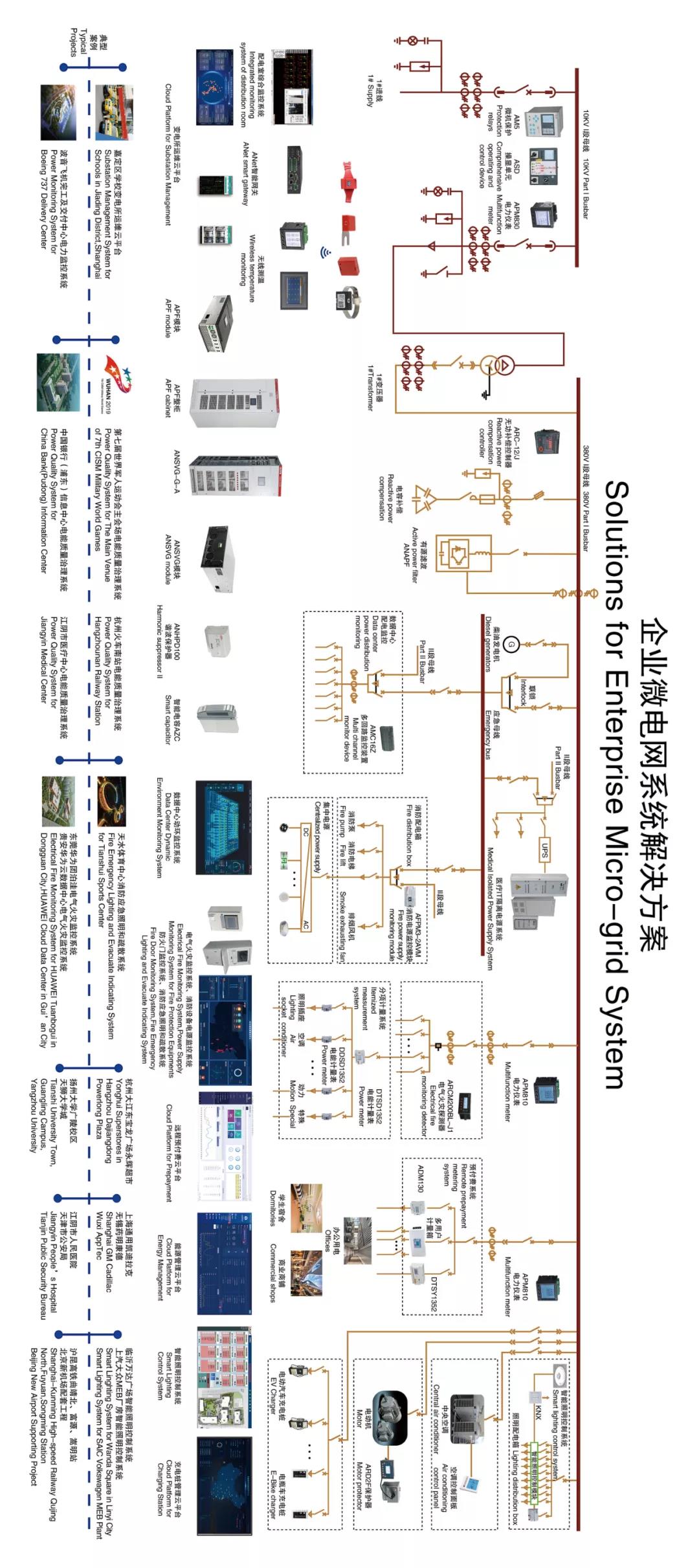

According to the requirements of integrated pipe gallery monitoring system, the scheme is configured with integrated monitoring system and subsystem solutions.

●Substation power monitoring subsystem

●Intelligent lighting control subsystem

●Electrical fire monitoring subsystem

●Fire fighting equipment power supply monitoring subsystem

●Fire door monitoring subsystem

●Fire emergency lighting and evacuation subsystem

●Water pump fan control system

●Dynamic loop monitoring subsystem of pipe gallery

●Integrated pipe gallery operation and maintenance management cloud platform

The scheme establishes an integrated monitoring system of "monitoring, control and maintenance" based on cloud platform. From the design of data acquisition, communication network, system architecture, linkage control and comprehensive data service, it solves the fundamental problems of strong internal interference, many users and complex coordination in the pipe gallery monitoring system, and greatly improves the reliability and manageability of system operation, The use and recovery efficiency of pipe gallery infrastructure, environment and equipment are improved.

4.1 power monitoring subsystem

The power monitoring system is mainly aimed at the 10 / 0.4kV ground substation. The high-voltage circuit of the substation is equipped with microcomputer protection devices and multi-functional instruments for protection and monitoring, and the 0.4kV outgoing line is equipped with multi-functional metering instruments for measuring and controlling the electrical parameters and energy consumption of the outgoing line circuit.

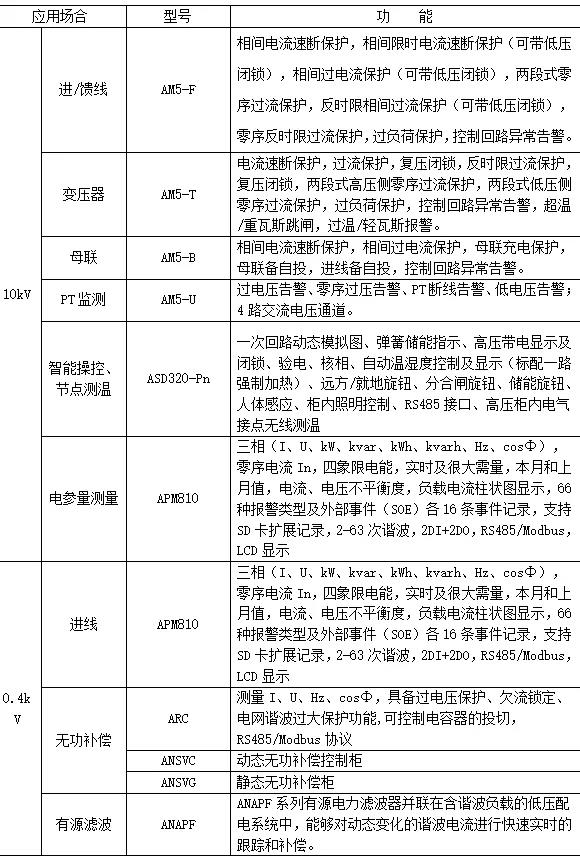

4.1.1 equipment selection of power monitoring subsystem

The main configurations of high and low voltage cabinets in the substation are as follows:

4.1.2 functions of power monitoring subsystem

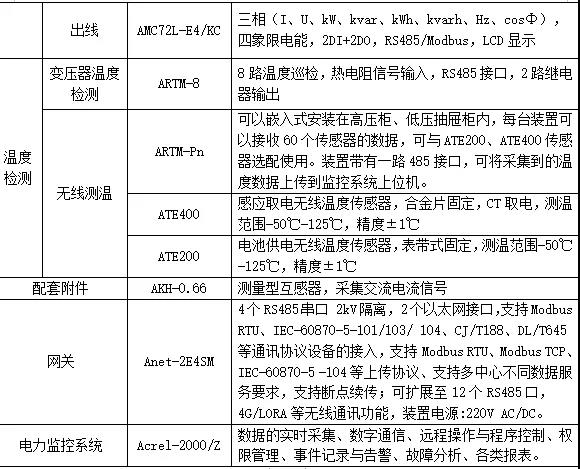

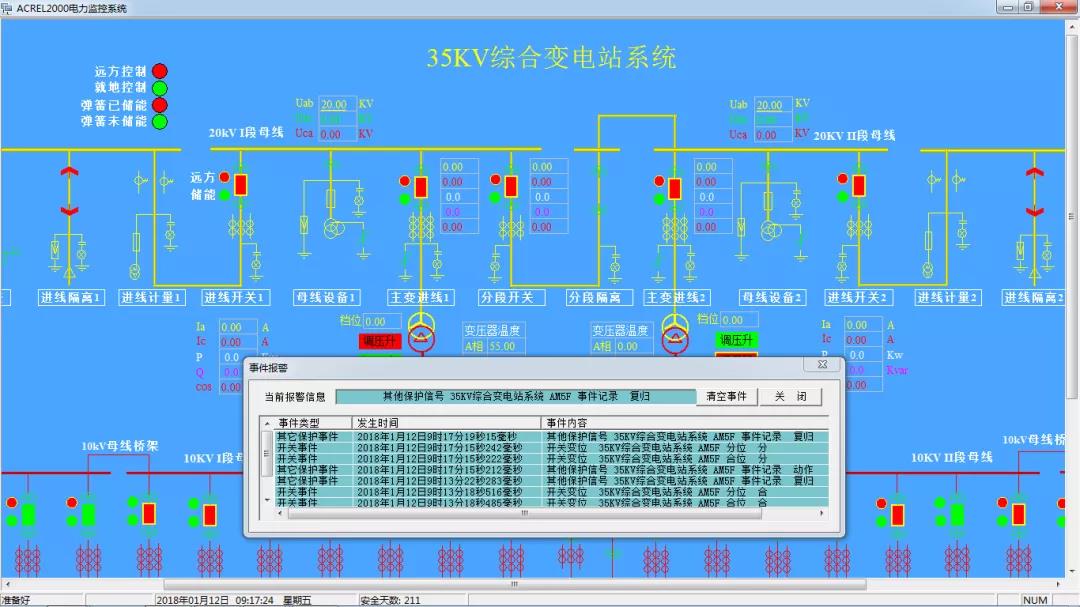

Real time monitoring

The system has friendly man-machine interface, visually displays the operation status of distribution lines in the form of distribution primary diagram, monitors the electrical parameter information such as voltage, current, power, power factor and electric energy of each circuit in real time, and dynamically monitors the on-off status of circuit breaker, disconnector and grounding knife of each distribution circuit, as well as relevant fault, alarm and other signals.

Detailed electrical parameter query

In the primary distribution diagram, you can directly view the detailed electrical parameters of the circuit, including three-phase current, three-phase voltage, three-phase total active power, total reactive power, total power factor and positive active electric energy, and you can view the 24-hour phase current trend curve.

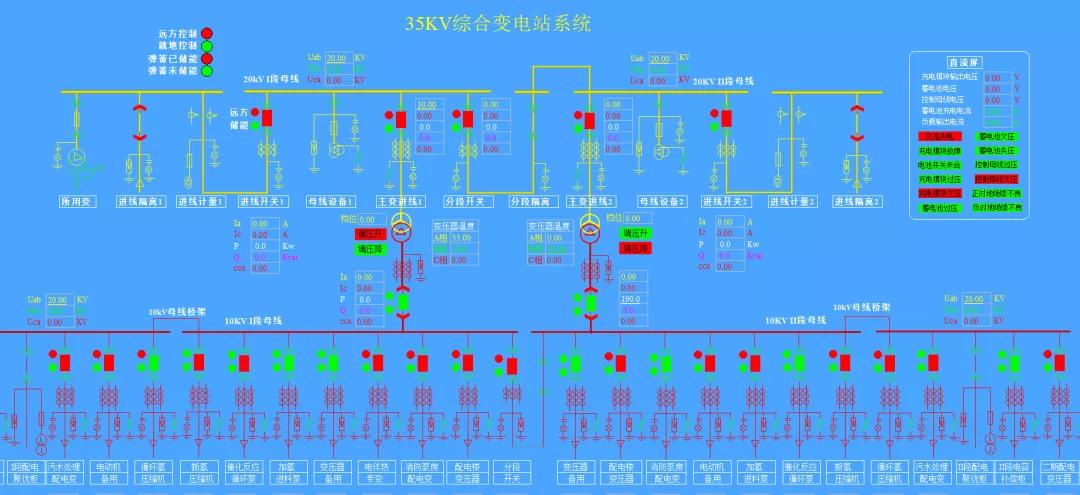

Run Report

Query the operation parameters of each circuit or equipment at the specified time. The electrical parameter information displayed in the report shall include: each phase current, three-phase voltage, total power factor, total active power, total reactive power, positive active electric energy, etc.

Real time alarm

The power monitoring system has the function of real-time alarm. The system can alarm the remote signal displacement, protection action, accident trip and other events of distribution circuit breaker, disconnector, grounding knife opening and closing action. The power monitoring system has real-time voice alarm function, and the system can send voice alarm for all events.

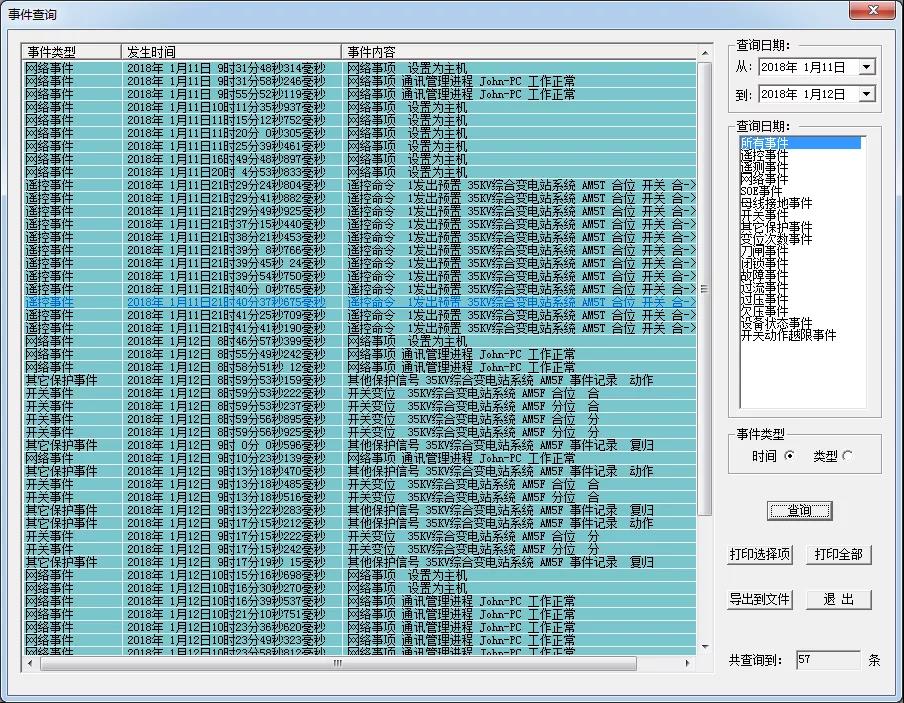

Historical event query

The power monitoring system can store and manage the event records of remote signaling displacement, protection action, accident trip, voltage, current, power and power factor out of limit, so as to facilitate users to trace the history of system events and alarms, query statistics and accident analysis.

Electric energy statistical report

The power monitoring system supports the integrity of the system with rich report body. The system has the function of regular meter reading summary and statistics. Users can freely query the power consumption of each distribution node in any time period since the normal operation of the system, that is, the statistical analysis report of the incoming power consumption of the node and the power consumption of each branch circuit.

User rights management

In order to ensure the safe and stable operation of the system, the power monitoring system has set up the user authority management function. Unauthorized operations (such as remote control, database modification, etc.) can be prevented through user authority management. The login name, password and operation authority of users at different levels can be defined to provide reliable security guarantee for system operation, maintenance and management.

Remote control operation

The power monitoring system can remotely operate the equipment within the whole distribution system. For example, the maintenance personnel of the distribution system can click the corresponding remote signal point of the circuit breaker through the main interface of the monitoring system to call out the remote operation interface, and can timely execute the corresponding operation commands of the dispatching system or the station.

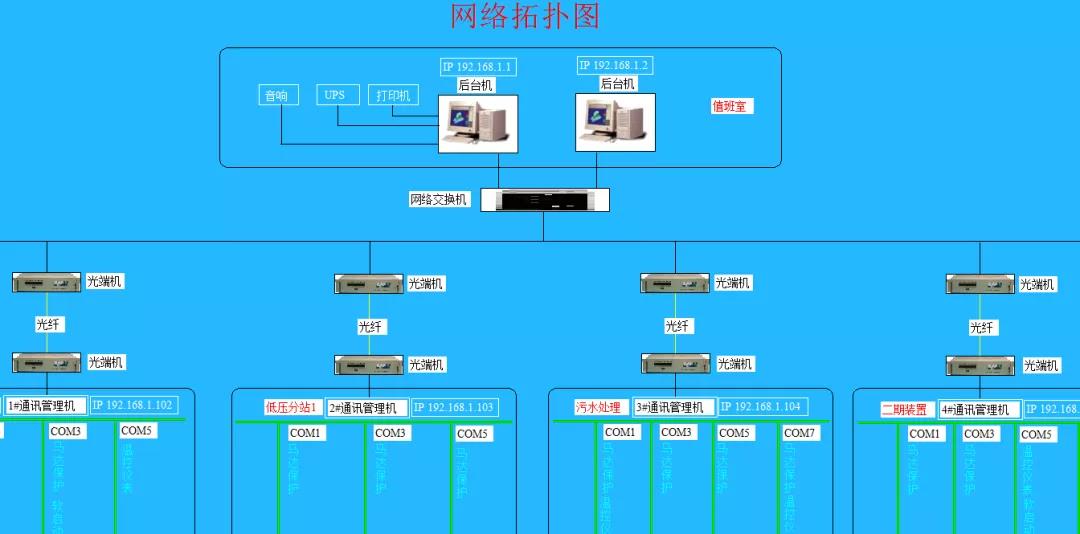

Network topology

The power monitoring system supports real-time monitoring of the communication status of each equipment connected to the system, and can completely display the network structure of the whole system; It can diagnose the equipment communication status online, and automatically display the faulty equipment or components and their fault parts on the interface in case of network abnormalities.

4.1.3 power quality control

The anapf series active power filter collects the system harmonic current through the current transformer, quickly calculates and extracts the content of each harmonic current through the controller, generates the harmonic current command, generates the compensation current in the same direction as the harmonic current amplitude through the power execution device, and injects it into the power system, so as to offset the harmonic current generated by the nonlinear load.

Product features:

●Flexible compensation mode: it can supplement both harmonic and reactive power. It can fully compensate the 2nd-51st harmonic or specify specific compensation

●Second harmonic compensation;

●Three phase imbalance can be controlled;

●Linear compensation, response time ≤ 5ms;

●It has a humanized human-computer interaction interface, through which you can see the real-time power quality information of the system and ontology. It is simple to operate and can be controlled remotely or locally;

●Imported IGBT is adopted, with high power density and high reliability;

●Digital control system with DSP high-speed detection and operation;

●Monitoring and display have remote communication interface, which can be monitored in real time through PC;

●The standard modular design shortens the delivery cycle and improves the reliability and maintainability.

Ansvg static var generator is a new power electronic device for reactive power compensation, harmonic control and imbalance regulation; The intelligent control system automatically adjusts the output of the module according to the linear dynamic requirements of the system; Ansvg complete machine is mainly composed of ansvg modules; It can complete the reactive power compensation of greater capacity, and the whole machine realizes human-computer interaction through a 7-inch touch screen. The touch screen communicates with the ansvg module via RS485.

Functional features:

●Flexible compensation mode: compensate the load reactive power and filter out harmonics within 5, 7, 9, 11 and 13 times;

●Three phase imbalance can be controlled;

●Linear compensation, response time ≤ 5ms;

●It has a humanized human-computer interaction interface, through which you can see the real-time power quality information of the system and ontology. It is simple to operate and can be controlled remotely or locally;

●Imported IGBT is adopted, with high power density and high reliability;

●Digital control system with DSP high-speed detection and operation;

●Monitoring and display have remote communication interface, which can be monitored in real time through PC;

●The standard modular design shortens the delivery cycle and improves the reliability and maintainability.

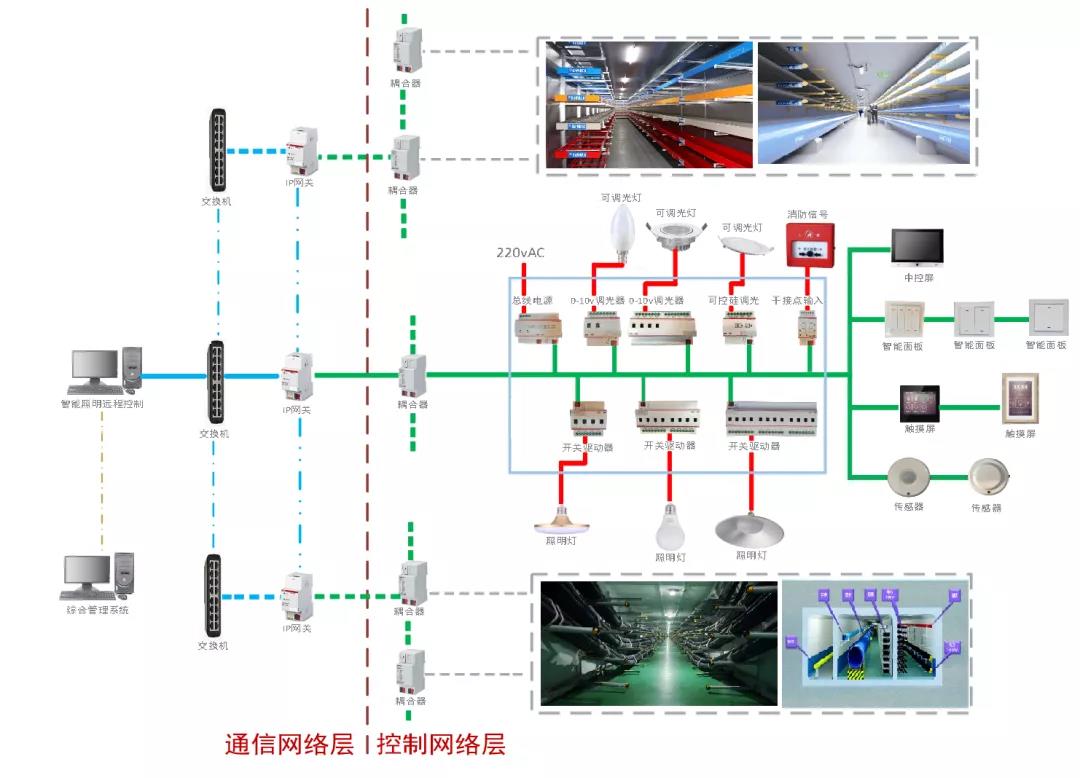

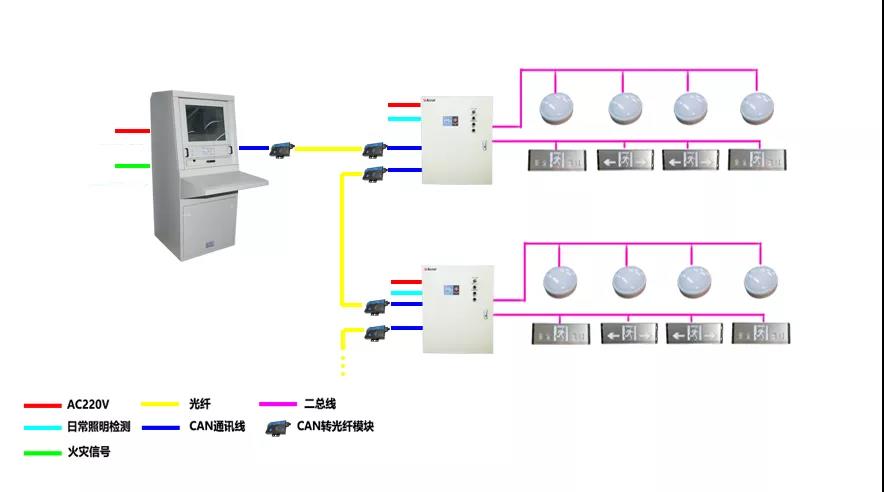

4.2 intelligent lighting control subsystem

In ASL1000 intelligent lighting control system, all devices are connected to each other through bus cables (2 & times; 2 & times; 0.8 four core shielded wire).

The modules to be installed in the distribution box mainly include bus power supply, switch driver, IP gateway, coupler, dry contact input module, etc. These modules are installed using 35mm standard guide rails.

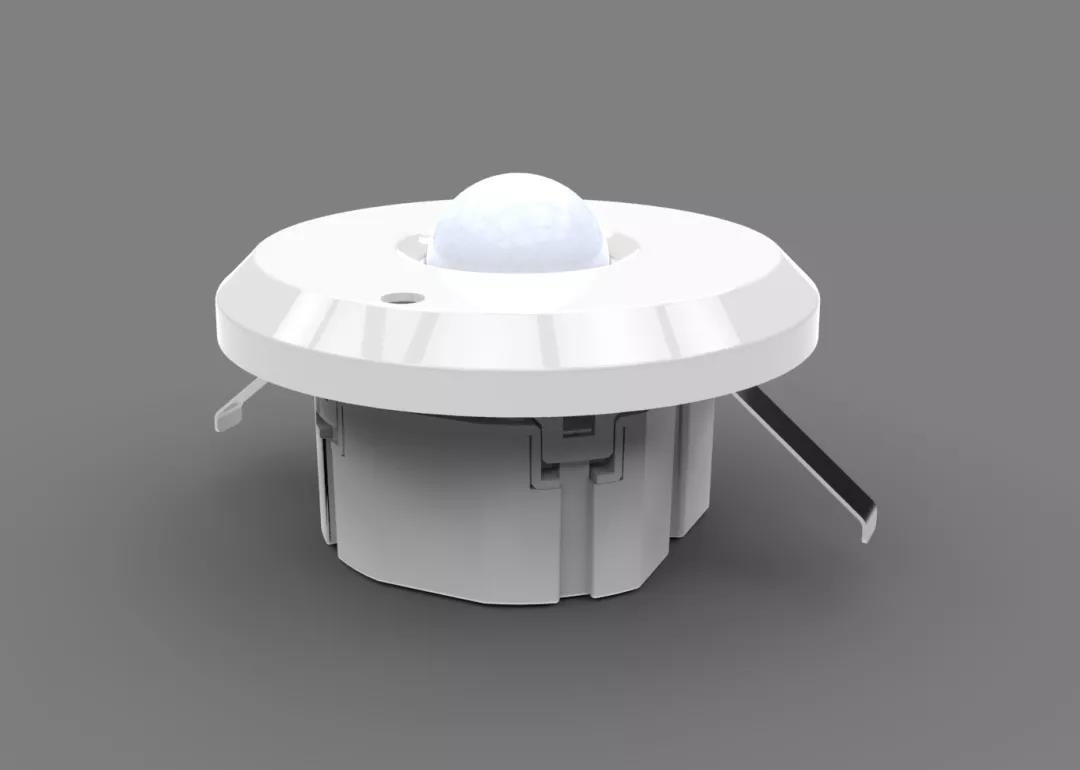

The modules to be installed on the control site mainly include sensors and intelligent panels. As the automatic control induction module, the sensor is embedded on the top of the pipe gallery. Someone can set the infrared induction control to turn on the light, and turn off the light within the set time after leaving. The intelligent panel and other manual control equipment can be embedded in the wall and installed at the partition entrance of the pipe gallery. In this way, the combination of automatic control, on-site control and remote control in the duty room can be realized.

4.2.1 equipment selection of intelligent lighting control subsystem

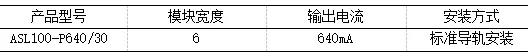

Power module

Function Description:

KNX / EIB system standard power supply, coupling bus signals, and monitoring the current of KNX / EIB system. In addition, the power supply of this series provides an auxiliary DC voltage of 30V to provide power for other peripherals (such as touch screen, IP gateway, etc.). The module can supply power to 64 devices with bus reset, overcurrent indication and short circuit protection.

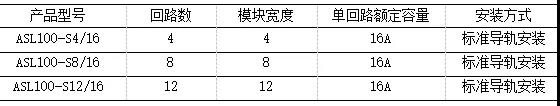

Switch driver

Function Description:

Light on driver, which supports KNX bus protocol and is used for switching control of equipment, has the functions of logic, delay, preset, scene, threshold switch, etc.

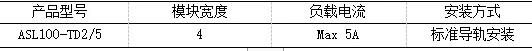

0-10V dimming driver

Function Description:

The 0-10V dimming module supports KNX bus protocol and is used to control the dimming circuit. It has soft on / off function. Each circuit can be called by 8 scenarios at the same time and can detect the circuit state. It is especially suitable for dimming incandescent lamps, LED lamps and low-voltage halogen lamps. It also has the functions of switch, scene, state feedback and so on.

Thyristor dimming module

Function Description:

The thyristor dimming module supports KNX bus protocol. As a dimming module, it can not only directly control the on-off state of the input power supply to control the on-off state of the load, but also adjust the input voltage through the phase control method to realize the dimming function of LED.

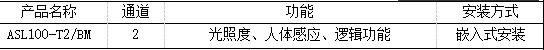

Human body sensing and illuminance sensor

Function Description:

Intelligent lighting sensor supports KNX bus protocol, can feel external signals and physical conditions (such as light and infrared), and transmit the induced information to other KNX modules (such as dimmer and switch driver) to realize its functions. It is mainly used in public walkways, halls, garages and other places requiring automatic control in intelligent lighting control system.

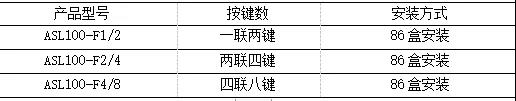

Smart panel

Function Description:

The intelligent panel supports KNX bus protocol and is used to receive key touch signals. It can realize the functions of switch, dimming, scene, curtain control, temperature regulation, alarm and so on by distinguishing short press and long press and combining different parameter configurations.

Dry contact input module

Function Description:

The dry contact signal input module supports KNX bus protocol and is used to accept external dry contact signal input. It can realize the functions of switch, dimming, scene, curtain control, value sending, counting, temperature regulation, alarm and so on through different parameter configurations.

4.2.2 functions of intelligent lighting control subsystem

Platform login

Double click the "intelligent lighting system" software on the computer desktop to enter the operation interface. At this time, the software is ready and waiting for the user to log in, as shown in the following figure:

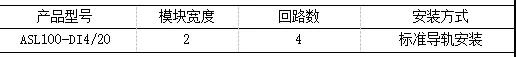

Software function interface

The software operation interface after logging in the account is shown in the figure below:

The software operation interface is divided into five areas, which are distinguished by five red boxes in the figure above.

Area 1: "login user area", which displays the currently logged in user name. Click to exit user login.

Area 2: "function list area", which displays software functions. The software functions are divided into plan view, module list, history, timing setting and maintenance setting. Click to enter different pages respectively. The contents of each interface will be described in detail below.

Area 3: "software title area", which displays fault prompt, software name, system time and exit software button.

Area 4: "function page display area", which is the specific operation display interface of software functions. By clicking the function list in area 2, the display of the corresponding area 4 function page will also change.

Area 5: "fault display area", when the module is offline, the gateway equipment is disconnected, or the status feedback is inconsistent with the control command issued, the fault alarm will occur, and the fault alarm information will be recorded and displayed in the interface. The prompt contents are fault time, module location and fault description.

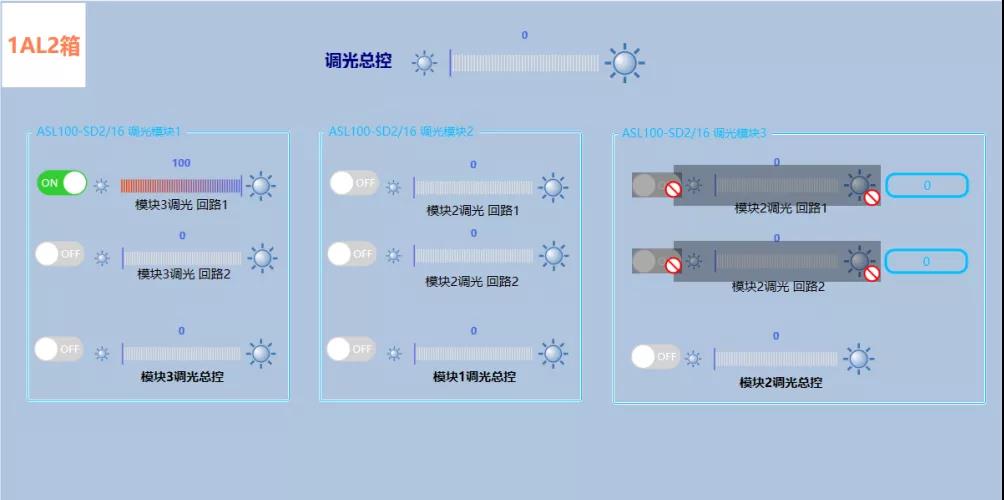

Plan view

Click the "plan view" button in the "function list area", as shown in the above figure. The plan view interface is mainly divided into two parts: layout list on the left and control display view on the right.

Layout list:

This area displays the floor monitored by the software and the layout of corresponding boxes and modules. The functions that can be realized include: switch control, dimming control, timing control, scene control, curtain control, current detection, loop fault judgment, plan and building master control, etc.

Control display view:

This area displays the control points of each item in the layout list, and feeds back the switching status of the on-site controlled loop in real time. The user can visually see the current status and feedback value of the module and realize remote centralized control.

Switch control control

Switch control can be realized for a single lighting circuit, and general control can be realized for each module, box, floor and user-defined zone. The switching status of the field controlled loop will be fed back in real time.

Dimming control

Drag the dimming control to dimming the lighting equipment from 0% to 100%. Click the symbols on the left and right sides to step dimming, with a step increase / decrease of 20%; The status of the field switch is fed back through the on-off status of the icon.

Click the module dimming single control to realize dimming control on the lighting circuit of a module;

Click dimming master control to realize dimming control for multiple lighting circuits.

Scene control control

Click the scene control, and the user can switch the preset scene independently.

Different scene modes and scene functions are displayed on the software interface, and the status of the corresponding scene is displayed whether it is on or off through the lighting of the icon.

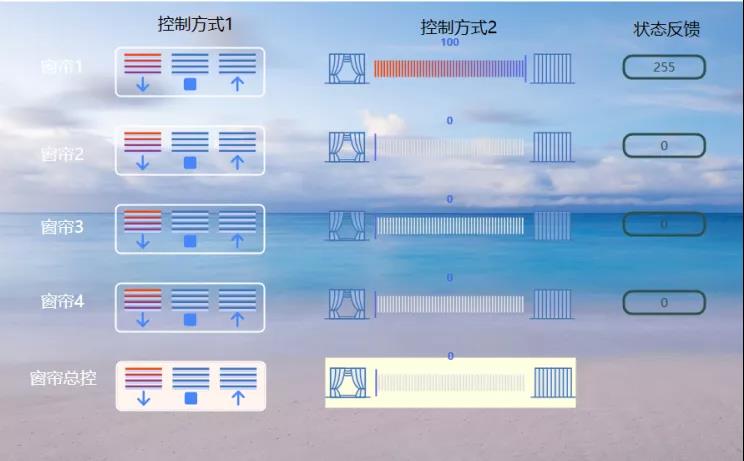

Curtain control:

Curtain control has two kinds of controls, one is the switch and step-by-step adjustment function; The other is stepless regulation and stepless regulation.

Click the curtain single control control to open and close the shutter / curtain or adjust the shutter angle;

Click the curtain master control icon to realize dimming control for multi-channel curtains;

Feed back the opening and closing state of the curtain on site through the on-off state of the icon, and the value represents the value of the relative action of the curtain.

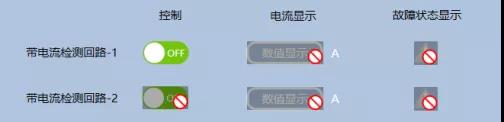

Current detection control

Read the current and switch control of all circuits of switch driver with current detection, and automatically analyze whether the circuit has fault status. Current value, fault status display and switch status will be fed back to the interface in real time.

Plan

Display the load position controlled by the module in the pipe gallery and control it through the right switch.

Building general control

Conduct regional general control.

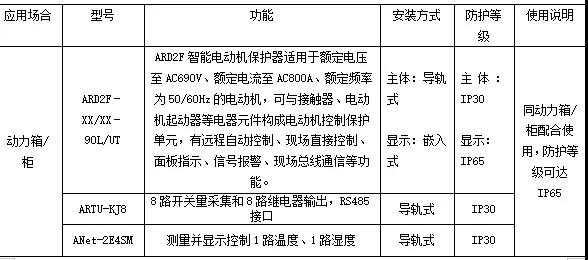

4.3 electrical fire monitoring subsystem

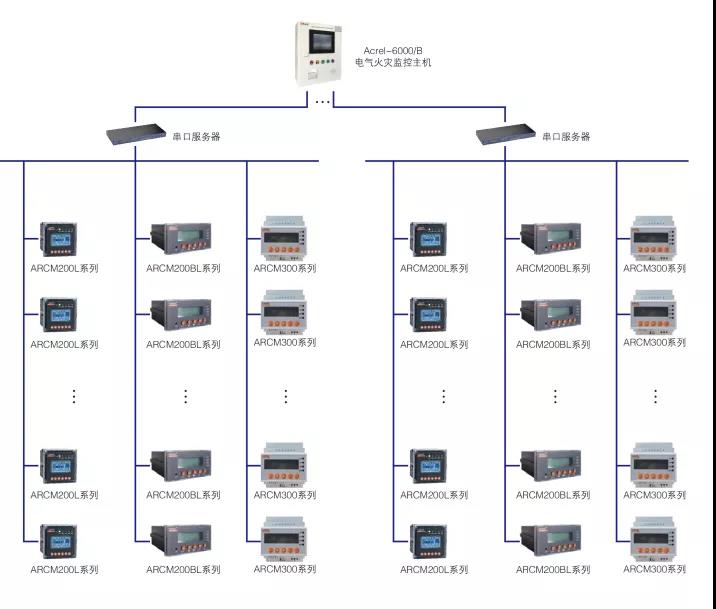

As the early warning subsystem of the automatic fire alarm system, the electrical fire monitoring system is composed of electrical fire monitoring host, electrical fire monitoring unit, residual current electrical fire detector and temperature measuring electrical fire detector. A complete set of electrical fire prevention monitoring system is formed through fieldbus, and the data can be integrated into the pipe gallery monitoring system.

The electrical fire monitoring system of the pipe gallery is set in the unit of fire compartment, and the collected data is uploaded to the monitoring host to realize the electrical safety early warning of the pipe gallery. The sensors set on site monitor the leakage current and cable temperature of the circuit of the distribution system, and send an alarm signal in real time in case of abnormality.

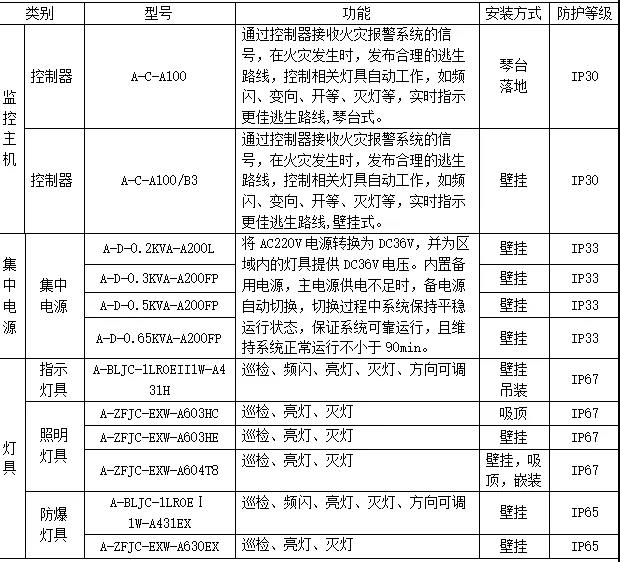

4.3.1 equipment selection of electrical fire monitoring subsystem

Note: the power box / cabinet used in the underground pipe gallery meets the relevant standards of the pipe gallery, and the protection grade reaches IP65.

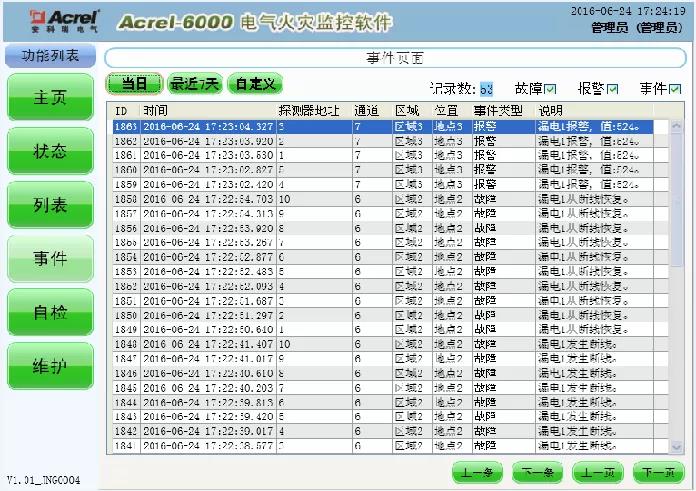

4.3.2 functions of electrical fire monitoring subsystem

Monitoring alarm function

The monitoring equipment can receive the residual current and temperature information of multiple detectors, send out audible and visual alarm signals during alarm, at the same time, the red "alarm" indicator on the equipment is on, the display screen indicates the alarm position and alarm type, records the alarm time, and the audible and visual alarm is maintained all the time, Until the "reset" button of the device or the "reset" button of the touch screen is pressed to remotely reset the detector. The audible alarm signal can also be manually eliminated by using the "silencing" button on the touch screen.

Control output function

When the monitored circuit gives an alarm, the control output relay is closed to control the protected circuit or other equipment. When the alarm is eliminated, the control output relay is released.

Fault alarm function

Communication fault alarm: in case of communication fault between the monitoring equipment and any connected detector or fault of the detector itself, the corresponding detector in the monitoring screen displays fault prompt, and the yellow "fault" indicator light on the equipment is on and sends out fault alarm sound.

Power failure alarm: when the main power supply or standby power supply fails, the monitoring equipment also sends audible and visual alarm signals and displays fault information. You can enter the corresponding interface to view the detailed information and remove the alarm sound.

Alarm record storage query function

In case of residual current, overtemperature alarm or communication and power failure, the alarm position, fault information, alarm time and other information shall be stored in the database. When the alarm is released and the fault is eliminated, it shall also be recorded. Historical data provides a variety of convenient and fast query methods.

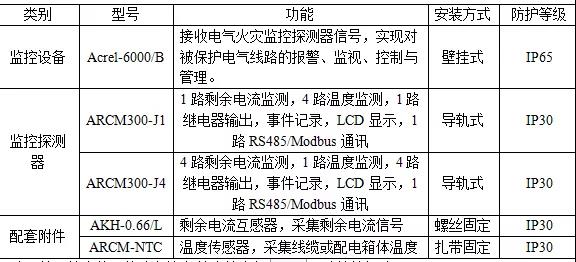

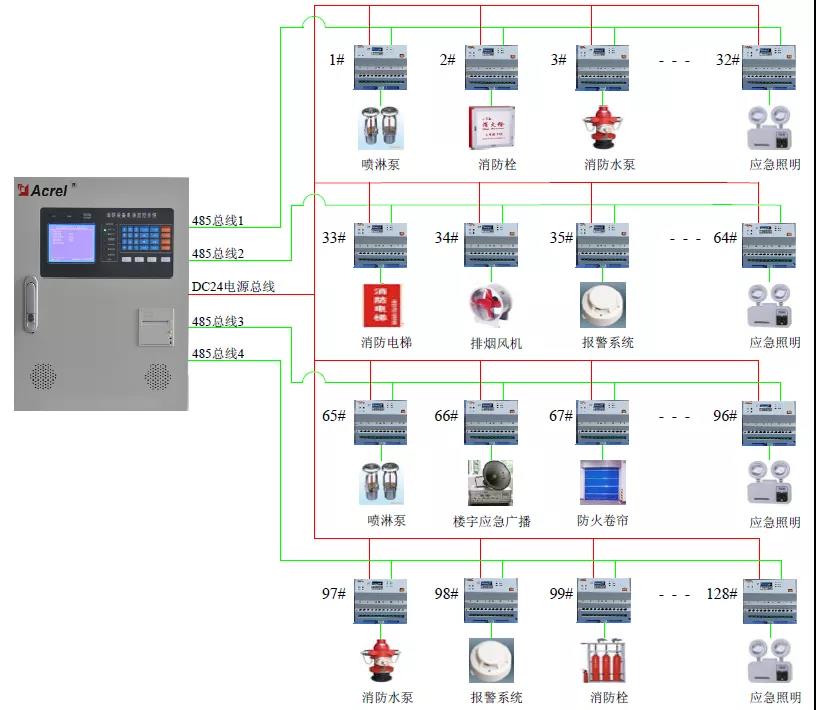

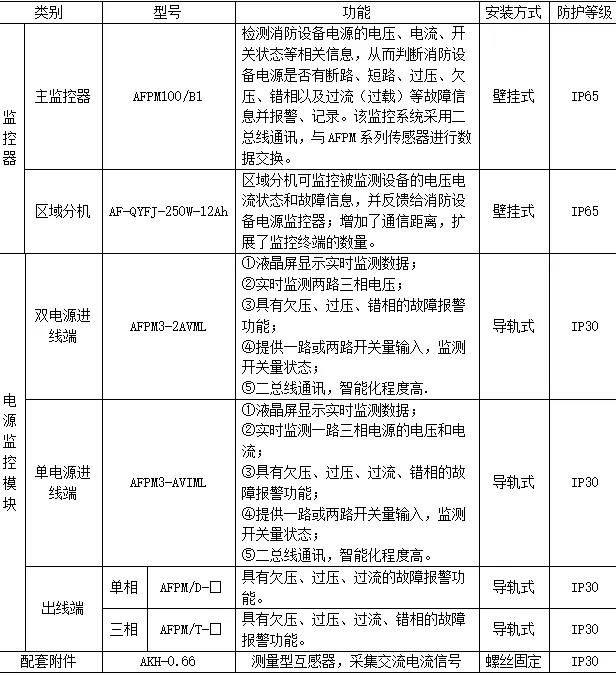

4.4 fire fighting equipment power supply monitoring subsystem

There are many power cables and gas pipelines in the pipe gallery, with high fire risk and many fire-fighting equipment. The main function of the fire-fighting equipment power supply monitoring system is to monitor whether the working power supply of the fire-fighting equipment is normal, so as to ensure that the fire-fighting equipment can be normally put into use in case of fire.

The fire protection equipment power supply monitoring system adopts the fire two bus. The fire compartment of the pipe gallery is set with an area extension to collect the power supply status of the fire protection equipment. The area extension receives the voltage, current information and switch status information of multiple sensors through the two bus, so as to realize the real-time monitoring of the working status of the power supply of the fire protection equipment.

4.4.1 equipment selection of fire equipment monitoring subsystem

4.4.2 functions of fire equipment monitoring subsystem

Monitoring function

The monitor receives the voltage, current and switch state information of multiple sensors through RS485 bus, so as to realize the real-time monitoring of the working state of the power supply of fire-fighting equipment. Send out audible and visual fault alarm signal in case of fault.

Control output function

When the monitored circuit gives an alarm, the output relay can be controlled to close to control the protected circuit or other equipment. When the fault is eliminated, the control output relay will be released.

Alarm function

System fault alarm: when the program cannot run normally, the monitoring equipment sends audible and visual alarm signals.

Other fault alarm: when the main power supply or standby power supply is abnormal, the monitoring equipment and sensor circuit have short circuit, open circuit and other faults, or the sensor sends various fault signals of the detected power supply, the monitoring equipment sends audible and visual alarm signals.

Record storage query function

In case of overvoltage, undervoltage, phase mismatch, overcurrent fault alarm or communication and power failure, the system will store the fault alarm position, fault information, fault alarm time and other information in the database. When the fault alarm is removed and the fault is eliminated, it will also be recorded.

Main and standby power switching function

In case of power failure, undervoltage and other faults of the main power supply, the monitoring equipment can automatically switch to the standby power supply; When the main power supply returns to normal power supply, it will automatically switch back to the main power supply to ensure the continuous and stable operation of the monitoring equipment during the switching process.

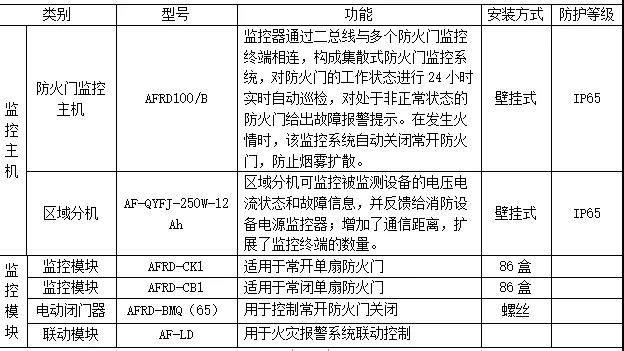

4.5 fire door monitoring subsystem

The comprehensive pipe gallery is designed as a 200m fire compartment, and fire doors are set at both ends of the fire compartment. The fire door monitoring system uses the fire two bus to connect the monitoring modules with communication function to monitor and control the state of the fire door. When the fire door has an abnormal position signal, the fire door monitor can send a fault alarm signal, indicate the fault alarm position and save the fault alarm information. In case of fire, close all normally open fire doors in the accident area to prevent smoke from spreading to the safe area.

4.5.1 equipment selection of fire door monitoring subsystem

4.5.2 functions of fire door monitoring subsystem

Fire linkage function

The system can be linked with the automatic fire alarm system. In case of fire, it can receive the signal sent by the fire alarm system, and issue the command to each terminal through the bus to automatically close all normally open fire doors and isolate fire sources and smoke.

Control output function

When the information of automatic fire alarm system is received, the control output relay is closed. When the alarm is eliminated, the control output relay is released.

Remote monitoring function

When the monitoring distance is far, the area extension can be used to extend the communication distance and power supply distance, and the monitoring information can be uploaded to the monitor. The monitor can remotely monitor and reset the monitoring module under the area extension.

4.6 fire emergency lighting and evacuation indication system

The pipe gallery has a long distance and narrow space. A fire compartment is set at 200m. In case of fire, the rapid evacuation is guided by fire emergency lighting and evacuation indicator lamps.

The number of lamps in each fire compartment is small, but the distance is long. A small power centralized power supply is set in each fire compartment to communicate with the controller through optical fiber. Due to the special environment of the pipe gallery, the lamps need to have a protection grade of above IP65, and explosion-proof lamps are also required in the gas tank.

4.6.1 equipment selection of fire emergency lighting and evacuation indication system

4.6.2 functions of fire emergency lighting and evacuation indication system

Fire linkage

The system is seamlessly connected with the automatic fire alarm system. When a fire occurs, the fire information is obtained in time, and the system automatically generates an escape route. At the same time, it can also enter the emergency state automatically and manually.

Fault alarm

The system uses fire two bus to connect the equipment and lamps with communication function. When the equipment and lamps in the monitoring system have short circuit, open circuit and other faults, the controller can send fault alarm signals, indicate the fault alarm location and save the fault alarm information, which greatly ensures the reliability of electrical safety.

System monitoring

The controller can monitor the working status of all components inside the system for 24 hours, and detect whether their working status is normal in real time, including centralized power supply, power distribution device and lamps. In case of fire alarm, it can quickly send instructions to control the display status of lamps.

System self-test

Automatically check whether all status indicators, display screens, speakers and printers in the controller are normal. The self inspection function is divided into routine self inspection, monthly inspection and annual inspection to regularly check circuit faults and eliminate potential safety hazards. The conventional self inspection mode is that all indicator lights flash and the display and audio devices sound; The monthly inspection mode is emergency work for 30 ~ 180 seconds every 30 days after power on for 24h; The annual inspection method is that the annual emergency working time shall not be less than 30min.

Record query

In case of emergency startup, failure and other events in the system, the controller can automatically record the event type, time, area and details of the event. The query date and range can be customized in the log record. The controller can store more than 10000 event records.

Guide optical flow

The controller can set the sequential flashing frequency of lamps through the software interface, which can be set at 2 ~ 32Hz.

4.7 water pump fan control system

There are a large number of water pumps and ventilation and smoke exhaust fans inside the pipe gallery to maintain the normal environment inside the pipe gallery.

Linkage drainage: when the water level in the sump exceeds the set water level, start the water pump for drainage, and stop the pump when the water level drops to the normal water level.

Linkage smoke exhaust / air system: each fire compartment is equipped with exhaust and smoke exhaust / air system, which is used for exhaust in normal conditions. When it is confirmed that fire / combustible gas is detected, the fan will be started automatically for smoke exhaust.

4.7.1 equipment selection of pump fan control system

4.7.2 functions of water pump fan linkage control system

Gateway anet-2e4sm has built-in embedded system, which can set control logic. After detecting the set conditions, it can start or stop fans, pumps and other equipment through control output.

4.8 dynamic loop monitoring subsystem of pipe gallery

The dynamic ring monitoring system of the pipe gallery collects the electrical parameters of the distribution boxes and cabinets inside the pipe gallery. Monitoring sensors such as gas (O2, CH4, H2S), temperature, humidity, smoke, water level and flooding are installed at the inlet and outlet and vent of each fire compartment in the comprehensive pipe Gallery. The data can be uploaded to the comprehensive monitoring system and linked with fans, pumps and other executive equipment.

Electrical parameter acquisition of distribution cabinet

Dtsd series products adopt din35mm guide rail mounting structure, with small volume, can measure electric energy and other electric parameters, can set parameters such as clock, rate and time period, high precision, good reliability, performance indicators meet various technical requirements of electric energy meters in national standards GB / t17215-2002, GB / t17883-1999 and power industry standard DL / t614-2007, and have electric energy pulse output function; RS485 communication interface can be used to realize data exchange with host computer.

Gas detector

Gas detector is an instrument for detecting the concentration of combustible, toxic and harmful gases. It is applicable to hazardous places with combustible or toxic gases. It can continuously detect the content of the measured gas in the air within the lower explosion limit for a long time, and transmit the real-time concentration to the monitoring platform through wireless or RS485 communication.

Temperature and humidity sensor

The temperature and humidity sensor is used for environmental temperature and humidity detection, and the data is uploaded to the monitoring platform through RS485 interface.

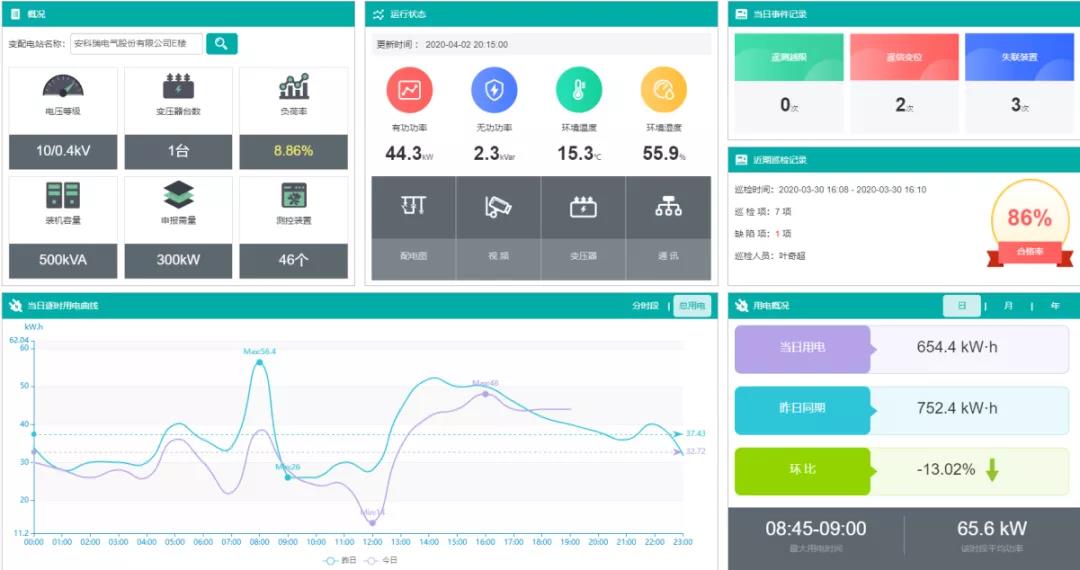

The main task of the integrated pipe gallery monitoring center is to ensure that the pipelines and control equipment in the pipe gallery can operate normally and respond quickly in case of accidents. Therefore, the pipe gallery monitoring center is the nerve center of the whole pipe gallery safety control system. Through automatic monitoring and detection equipment, the status data in any corner of the pipe gallery can be quickly transmitted and collected in the monitoring center, So that managers can easily grasp all the situations at any time. The system collects the information of pipe gallery power supply system, smoke detector, drainage and smoke exhaust system, ambient temperature and humidity, combustible gas detection, access control, intrusion detection, video and so on. In case of abnormality, the system pushes the alarm signal through SMS or app, and can send work orders and carry out tracking and closed-loop processing.

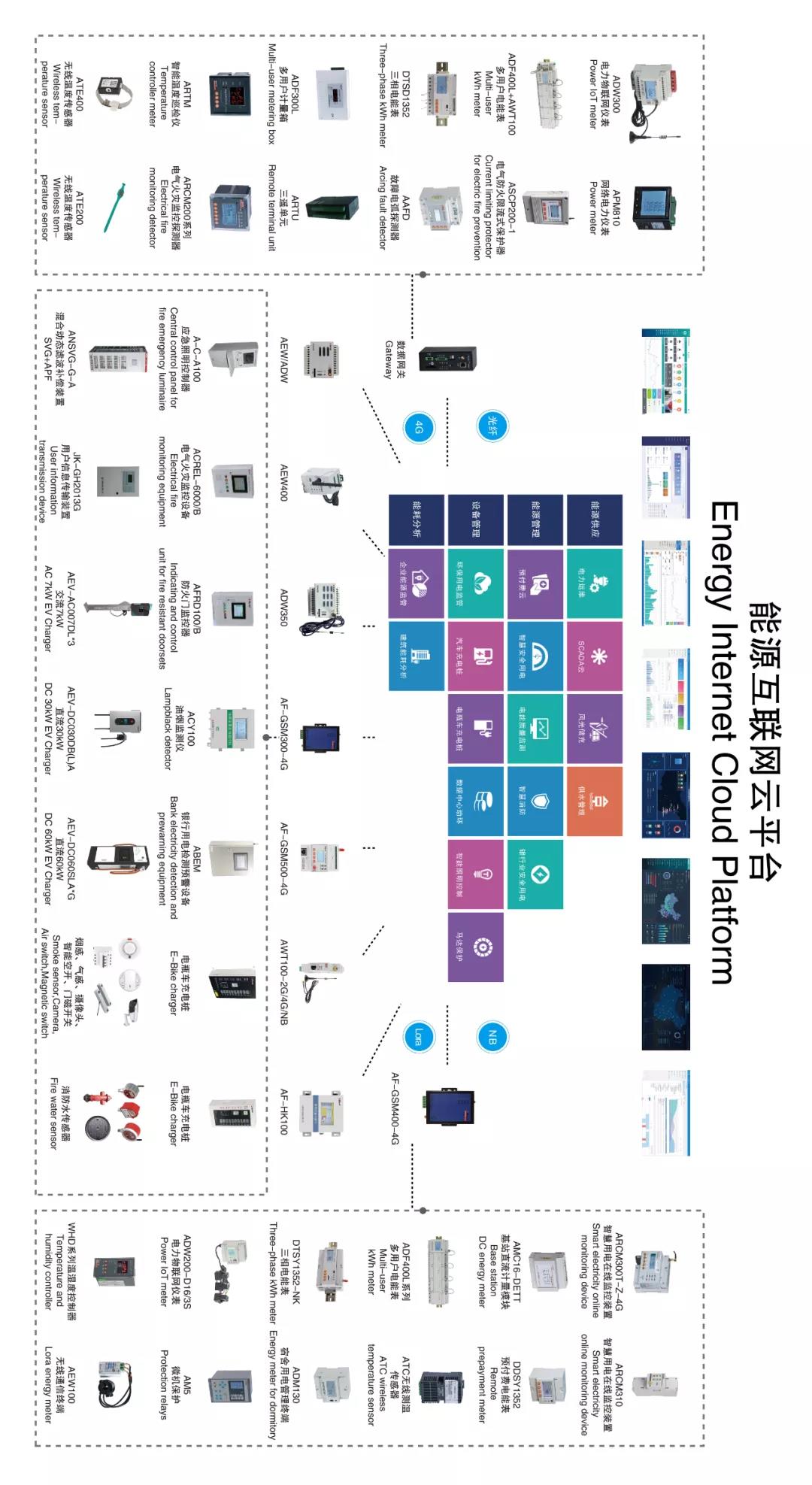

5.1 platform login

The software adopts B / S architecture. Open the cloud platform link with a browser, enter the account name and permission password, and log in to prevent unauthorized personnel from browsing relevant information.

5.2 platform navigation

The home page of the platform displays the overview of the user managed transformation and distribution station, including monthly energy consumption report, selected transformation and distribution station status, transformer status, operation and maintenance center and kanban.

Substation status

Substation status includes overview, operation status, event record of the day, hourly power consumption curve of the day and power consumption overview.

Transformer status

Transformer status enables users to query the transformer power, load rate, and other operation status data of all or a station, and supports ranking in ascending and descending order according to load rate and power.

Operation and maintenance center

The operation and maintenance center displays the location and total amount information on the map of the substation managed by the current user.

5.3 power monitoring

Power monitoring includes power data, transformer monitoring, operation report, distribution diagram, power value table, operation daily report, average power factor monitoring and Statistics page.

5.4 power consumption analysis

Power consumption analysis includes energy consumption report, year-on-year analysis, month on month analysis, power centralized reading, metering and line loss.

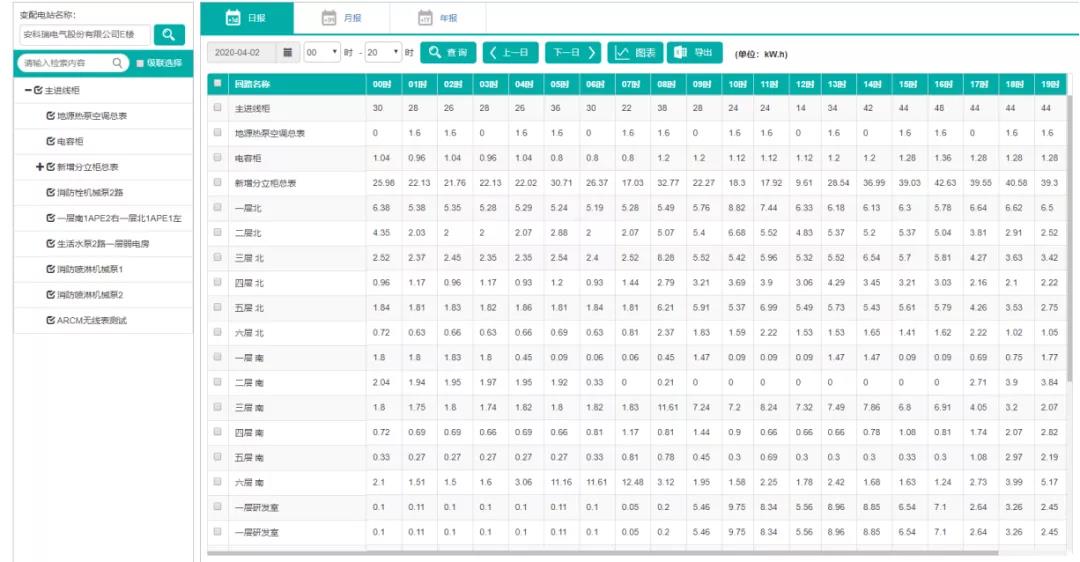

Energy consumption report

The energy consumption report shows the energy consumption data of each circuit, including daily report, monthly report and annual report. The daily report shows time-sharing energy consumption, the monthly report shows daily energy consumption, and the annual report shows monthly energy consumption. The report can be exported.

5.5 event record

The event record is convenient for the operation and maintenance personnel to view the records of analysis equipment, such as circuit breaker on / off, door opening and closing, current and voltage out of limit alarm, smoke alarm, gas concentration out of limit alarm, flooding alarm, fault alarm, SMS log, platform operation log, etc.

5.6 safe use of electricity

Safe power use includes leakage monitoring and cable temperature monitoring.

Leakage monitoring

Leakage monitoring shows the leakage current, cable temperature and alarm status of the selected transformation and distribution station.

Cable temperature monitoring

The cable temperature monitoring interface shows the cable temperature of the selected transformation and distribution station, select the monitoring points to view, and click query to view the historical data of cable temperature.

5.7 operating environment

The operating environment includes environmental monitoring, video monitoring, ambient temperature and humidity, instrument communication status, gateway communication status, video monitoring, video equipment status, etc.

Environmental monitoring

Environmental monitoring shows the environmental status of the substation, including environmental temperature and humidity, water immersion, smoke, door status and other information.

Video surveillance

The video monitoring shows the current real-time picture (live video). Select a power transformation and distribution station to view the video information in the power transformation and distribution station.

Ambient temperature and humidity

The ambient temperature and humidity displays the ambient temperature and humidity information recorded by the instruments in the substation and can be exported to excel.

Video device status

The status of video equipment shows the online status of video equipment in the substation.

5.8 equipment control

Equipment control includes remote control definition, lighting control and control operation log.

Lighting control

Lighting control can control the light bulb on and off. Select "transformation and distribution station", click to check the equipment to be controlled, click the "control" button, select the equipment status on the pop-up layer, and click "OK".

5.9 equipment management

Equipment management includes equipment definition, equipment file and equipment report, and maintenance of substation equipment in equipment file.

Equipment archives

Select a substation in the equipment file and import the equipment definition template. There are operations such as adding, modifying, deleting and copying to maintain and manage the substation equipment.

Equipment Report

The equipment report shows the equipment status of each substation, obtains the recommended replacement time according to the installation time and warranty period filled in the equipment file, and prompts the user to replace the equipment within 7 days of the recommended replacement time.

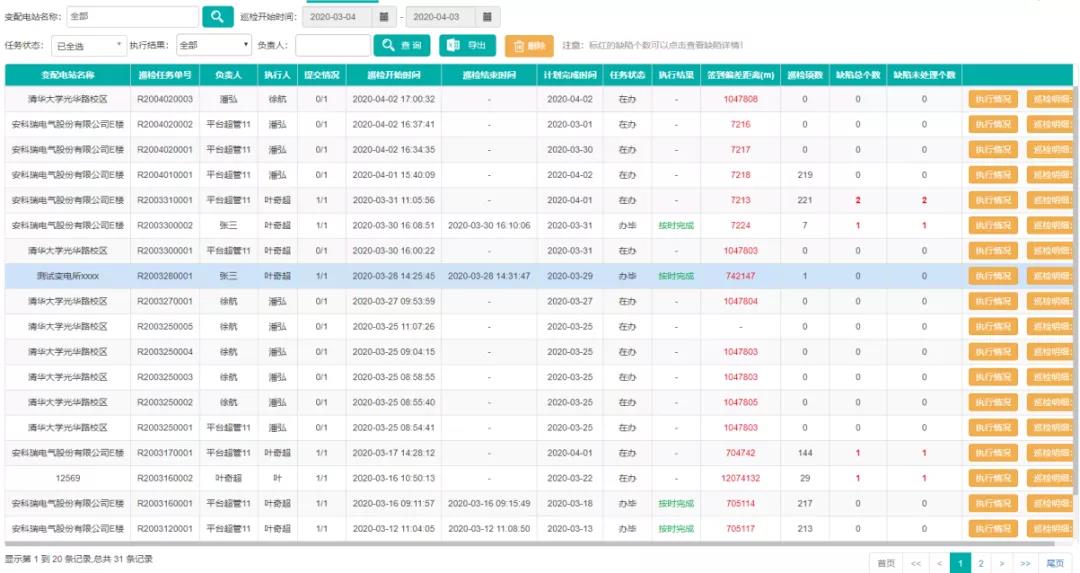

5.10 operation and maintenance management

Operation and maintenance management includes task management, patrol inspection records and defect records. Task management can complete the creation, release and query of task completion; Patrol inspection record is the execution status and execution details of patrol inspection tasks, and defect record is the query of creation, release and completion status of defect elimination tasks.

Task management

On the task management page, you can publish patrol inspection or defect elimination tasks, view the status and completion of patrol inspection or defect elimination tasks, and click View task to view specific patrol inspection information.

Patrol inspection record

The patrol inspection record shows the completion of patrol inspection tasks and patrol inspection details.

Defect record

The defect record records the defect information uploaded during the operation and maintenance patrol inspection of each substation.

5.11 app support

The power operation and maintenance mobile phone supports seven modules: "monitoring system", "equipment file", "to-do list", "patrol record", "defect record", "document management" and "user report", and supports primary diagram, demand, value, power consumption, video, curve, temperature and humidity, year on year, month on month, power quality, variable event alarm query, equipment file query, to-do event processing, patrol record query, user report, document management, etc.

(please rotate the phone to the horizontal screen to view)

The contact information of the permanent staff of ankerui Hebei region is as follows:

| Region | Full name | Telephone |

| Shijiazhuang | Wang Shuozhi |

13651840746 |

| Shijiazhuang | Chen Zhanchao |

13651860145 |

| Shijiazhuang | Zhang Yuxiang |

15021917503 |

| Hengshui | Xiao Pu Zheng |

18702115089 |

| Tangshan, Qinhuangdao | Jian Song Zhang |

18702122652 |

| Chengde | Zhang Jianlu |

18721095572 |

| Baoding | Fang Yuan |

18217356184 |

| Baoding | Bu Yuhang |

18721293347 |

| Zhangjiakou | Zhang boce |

18701996591 |

| Handan | Wang Xingdong |

15021996057 |

| Handan | Liu Chen |

13482142473 |

| Xingtai | Luo Yanin |

18217358534 |

| Cangzhou | Zhang Zhen |

13661797742 |

| Langfang | Chen Peng | 18702111609 |

This content comes from the small knowledge of network / Internet of things technology. This website only provides reprint. The views, positions and technologies of this article have nothing to do with this website. If there is infringement, please contact us to delete it!

Copyright © Shenzhen Kinghelm Electronics Co., Ltd. all rights reservedYue ICP Bei No. 17113853